Harley Dealers!

- Sev

- Site Supporter - Gold

- Posts: 7352

- Joined: Sun Jun 06, 2004 7:52 pm

- Sex: Male

- Location: Sherwood Park, Alberta

Speaking from experience now, changing a tire is a relatively simple job, especially since you have a tubeless type tire. You can do it safely and easily with a pair of steel hand levers, some water, and a little common sense/care.

I'll come back and post the steps (hopefully with pictures) after class. Once you have the tire mounted I imagine pretty much any shop would be willing to bead (you can do this yourself) and balance it (you can do this too) for you.

I'll come back and post the steps (hopefully with pictures) after class. Once you have the tire mounted I imagine pretty much any shop would be willing to bead (you can do this yourself) and balance it (you can do this too) for you.

Of course I'm generalizing from a single example here, but everyone does that. At least I do.

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

- CNF2002

- Site Supporter - Silver

- Posts: 2553

- Joined: Fri Sep 16, 2005 1:56 pm

- Sex: Male

- Location: Texas

Speaking from experience now, changing a tire is a relatively simple job, especially since you have a tubeless type tire.

Don't I need a special table to lock down the wheel while I mount the tire?

CheckYou can do it safely and easily with a pair of steel hand levers,

some water,

For me or the wheel?

How much is a little?and a little common sense/care.

If I'm going to replace the tire, I'd prefer to do the whole thing (including beading and balancing)...if I only save about a hundred dollars by doing it solo, so if I have to pay someone $20-30 to finish it, it's not worth the effort really.

I suppose this would be a good time to buy that bike jack.

2002 Buell Blast 500 /¦\

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

- CNF2002

- Site Supporter - Silver

- Posts: 2553

- Joined: Fri Sep 16, 2005 1:56 pm

- Sex: Male

- Location: Texas

Hmm, at a glance at the manual I am going to need:

5 new bolts

5 new washers (all at dealer prices no less)

some loctite

I will not have the equipment to check the rim runout

a wheel bearing removal tool

rim protectors

tire tools (for breaking the bead and reinstalling)

I will not have the equipment to check the tire runout

a balancing stand and wheel weights

I really don't see how I could perform this job in a home garage

Balancing stand: $160

Bolts/washers: $15

Bearing removal tool: $30

4 tire tools (bars): $45

couldn't find any online sources for rim protectors. I'll spend about 3 times on tools what I would for one change and I haven't even bought the tire yet! Perhaps this is a future expense, since the cost of the tire replacement is going to hurt our budget right now let alone more for tools

5 new bolts

5 new washers (all at dealer prices no less)

some loctite

I will not have the equipment to check the rim runout

a wheel bearing removal tool

rim protectors

tire tools (for breaking the bead and reinstalling)

I will not have the equipment to check the tire runout

a balancing stand and wheel weights

I really don't see how I could perform this job in a home garage

Balancing stand: $160

Bolts/washers: $15

Bearing removal tool: $30

4 tire tools (bars): $45

couldn't find any online sources for rim protectors. I'll spend about 3 times on tools what I would for one change and I haven't even bought the tire yet! Perhaps this is a future expense, since the cost of the tire replacement is going to hurt our budget right now let alone more for tools

2002 Buell Blast 500 /¦\

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

- Sev

- Site Supporter - Gold

- Posts: 7352

- Joined: Sun Jun 06, 2004 7:52 pm

- Sex: Male

- Location: Sherwood Park, Alberta

Wait wait wait, you need to replace your wheel bearings etc etc etc? Or just replace the tire?

You don't need a stand to do the tire replacement, I've been using a piece of cardboard on the floor to prevent scratches. Rim protectors are just pieces of plastic that fit over the rim so you don't scratch it. Wrap your tire irons in duct tape.

Checking rim runout can be done with the axle and a spray can... but I thought Buell's have cast wheels (no spokes) so you don't need to check them for runout. They are either true or they are "messed" and need to be replaced. If a cast wheel isn't correct, there's no way to fix it.

So you need:

2 tire irons

water (or some tire approved lube but we use water).

You'll be paying for the new bolts and washers regardless.

If you get it mounted, I'll bet you money nearly any shop will balance it for you.

If you remove the bearings they should be junked regardless, because you're going to be brinelling them with the force that you're putting on them, so a pick and a hammer is good enough, just make sure you don't pound them back in. But you only need to replace bearings if yours are shot.

The short version of what to do is:

1) let the air out

2) remove the valve in the valve stem

3) lay the tire on its side on a piece of cardboard and step on the rubber to break the bead off the rim

4) flip over and repeat

4) a) lube the bead (lip) with water

5) fit the curved end of one of your tire irons under the bead (lip) of the tire and lever it up over the rim, place the other 5 inches away and do the same

6) work your way around until you've got 1 whole side off

7) do the same thing for the other side of the tire, making sure you pull it off to the same side

throw away old tire

throw away old tire

9) lube the new tire with water

10) line the light spot (part with a dot) of the tire up with the valve stem

11) starting at the valve stem shove the tire onto the rim making sure to push evenly

12) use the flat side of the tire iron to push the first bead over the rim taking small 4-5 inch sections at a time

13) use the flat side of the tire iron to push the other side of the tire on the wheel in small sections, take your time standing on the part you started will help to keep it in place

14) lube the beads again with water and put air into it you will hear 2 pops (maybe BANGS) as the tire fits into the beads

take it to a shop to be balanced OR

15) balance it by putting it through the axle and resting the axle on a level surface (it MUST be level)

16) spin the tire a couple of times, marking the lowest spot each time

17) add weight opposite that spot (highest)

18) only add weight to one place otherwise you can negate weights that you've already added, but continue to add weights until the tire does not stop in the same spot twice

replace the cheap taped on weights with real weights and you're good to go

it is not necessary to spin the wheel really hard when you are balancing

It's not easy the first couple of times, but once you get used to it, you can do it in 10 minutes. 2 weeks ago I wouldn't know which side of a tire iron to hold.

You don't need a stand to do the tire replacement, I've been using a piece of cardboard on the floor to prevent scratches. Rim protectors are just pieces of plastic that fit over the rim so you don't scratch it. Wrap your tire irons in duct tape.

Checking rim runout can be done with the axle and a spray can... but I thought Buell's have cast wheels (no spokes) so you don't need to check them for runout. They are either true or they are "messed" and need to be replaced. If a cast wheel isn't correct, there's no way to fix it.

So you need:

2 tire irons

water (or some tire approved lube but we use water).

You'll be paying for the new bolts and washers regardless.

If you get it mounted, I'll bet you money nearly any shop will balance it for you.

If you remove the bearings they should be junked regardless, because you're going to be brinelling them with the force that you're putting on them, so a pick and a hammer is good enough, just make sure you don't pound them back in. But you only need to replace bearings if yours are shot.

The short version of what to do is:

1) let the air out

2) remove the valve in the valve stem

3) lay the tire on its side on a piece of cardboard and step on the rubber to break the bead off the rim

4) flip over and repeat

4) a) lube the bead (lip) with water

5) fit the curved end of one of your tire irons under the bead (lip) of the tire and lever it up over the rim, place the other 5 inches away and do the same

6) work your way around until you've got 1 whole side off

7) do the same thing for the other side of the tire, making sure you pull it off to the same side

9) lube the new tire with water

10) line the light spot (part with a dot) of the tire up with the valve stem

11) starting at the valve stem shove the tire onto the rim making sure to push evenly

12) use the flat side of the tire iron to push the first bead over the rim taking small 4-5 inch sections at a time

13) use the flat side of the tire iron to push the other side of the tire on the wheel in small sections, take your time standing on the part you started will help to keep it in place

14) lube the beads again with water and put air into it you will hear 2 pops (maybe BANGS) as the tire fits into the beads

take it to a shop to be balanced OR

15) balance it by putting it through the axle and resting the axle on a level surface (it MUST be level)

16) spin the tire a couple of times, marking the lowest spot each time

17) add weight opposite that spot (highest)

18) only add weight to one place otherwise you can negate weights that you've already added, but continue to add weights until the tire does not stop in the same spot twice

replace the cheap taped on weights with real weights and you're good to go

it is not necessary to spin the wheel really hard when you are balancing

It's not easy the first couple of times, but once you get used to it, you can do it in 10 minutes. 2 weeks ago I wouldn't know which side of a tire iron to hold.

Of course I'm generalizing from a single example here, but everyone does that. At least I do.

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

- CNF2002

- Site Supporter - Silver

- Posts: 2553

- Joined: Fri Sep 16, 2005 1:56 pm

- Sex: Male

- Location: Texas

Thanks! No, the Blast doesnt have spokes, it is a cast rim. The manual does still say to check the runout. It has instructions for lateral and radial runout specifically on a cast rim.

I do not have to replace the wheel bearings, but the manual instructs to remove them for inspection. Apparently I can also get away with not removing the sprocket (hence not needing the bolts) I do not know, that will be something I will need to see when I get it all apart.

How much force is necessary to break the bead? If it can be done simply by stomping on it, it can't be much!

If I do this I am going to set aside a whole day and take my time. My biggest concern is just properly mounting the tire, correctly sealing the bead, and such.

Reading the manual again it says the sprocket and cover must be removed for disassembly. I can't imagine I need to disassemble the wheel to replace the tire. The tire removal procedure instructs to remove the sprocket, but this also might be because it also instructs to use specific machines to remove the tire that may not fit with the sprocket on. I can always go out and buy the bolts later if I have to.

Since this is my first time, is it relatively simple to get the tire on right the first time, or will I end up doing it several times to get it aligned/positioned correctly?

PS: Thanks for all your help!!

I do not have to replace the wheel bearings, but the manual instructs to remove them for inspection. Apparently I can also get away with not removing the sprocket (hence not needing the bolts) I do not know, that will be something I will need to see when I get it all apart.

How much force is necessary to break the bead? If it can be done simply by stomping on it, it can't be much!

If I do this I am going to set aside a whole day and take my time. My biggest concern is just properly mounting the tire, correctly sealing the bead, and such.

Reading the manual again it says the sprocket and cover must be removed for disassembly. I can't imagine I need to disassemble the wheel to replace the tire. The tire removal procedure instructs to remove the sprocket, but this also might be because it also instructs to use specific machines to remove the tire that may not fit with the sprocket on. I can always go out and buy the bolts later if I have to.

Since this is my first time, is it relatively simple to get the tire on right the first time, or will I end up doing it several times to get it aligned/positioned correctly?

PS: Thanks for all your help!!

2002 Buell Blast 500 /¦\

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

- Sev

- Site Supporter - Gold

- Posts: 7352

- Joined: Sun Jun 06, 2004 7:52 pm

- Sex: Male

- Location: Sherwood Park, Alberta

You don't HAVE to do it yourself. But if you're going to... there's a couple of things you should know.

A removed bearing is a compromised one, if you applied force to the inner circle to remove it (pulled or punched it out) then you've potentially damaged it, and should not reuse it.

To check for wheel bearing function leave it on the swingarm, or the forks, and holding the frame still try to... well you grab the tire at two spots opposite each other and push one side away and one side towards, then just back and forth. You're checking for lateral movement against the axle. I cannot think of a better way to describe it then that. If you feel any movement at all they need to be replaced. A bearing is engineed to within three ten thousandths of an inch. To fine for you to pick up any movement.

Do this at a couple of spots along the rim (you can rotate it to make it easier) and there should be no play. Spin the rim and listen for catching or rough movement... if you think there's a problem replace them.

Like I said above those are the instructions for doing it, I'll see if I cannot get some pictures of me doing it next time I change one or...

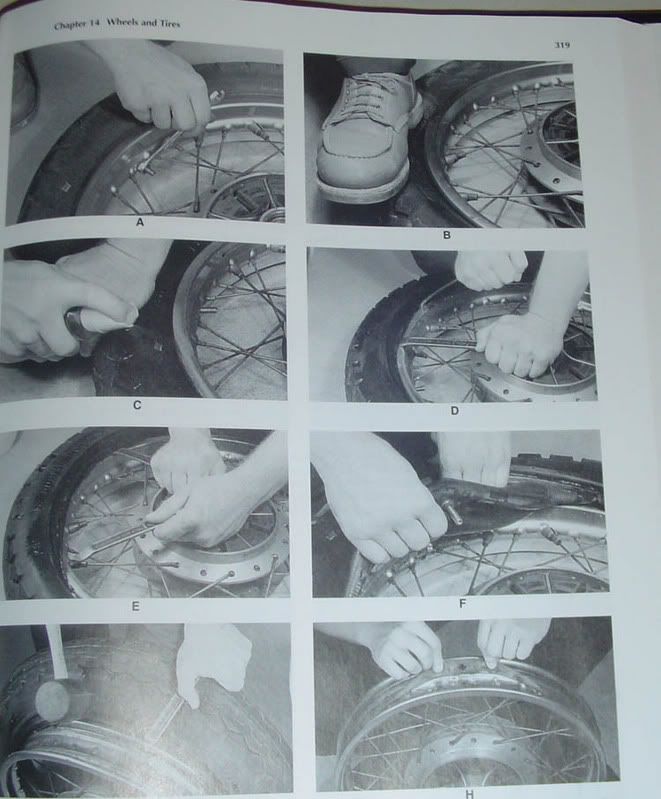

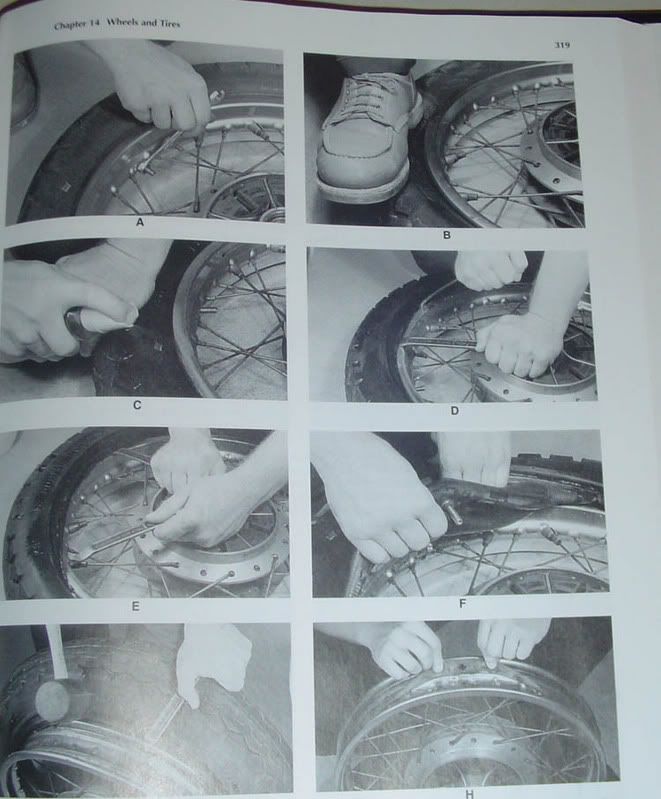

Here is a pic that shows the steps to change a tube-type tire.

You can ignore the part about removing the tube and reinstalling it. you might have trouble breaking the bead with your foot, there are machines that can do it for you. Alternately if you aren't using the same tire ever again just use a table vice to pinch the tire right next to the rim until it pops off teh bead (do not let it hit the rim) and then stomp the rest out.

If you want to check the runout quickly and/or easily, after the tire is off the wheel reinstall the wheel in the swing arm or forks keeping it off the ground. Set up a spray can with a straw on it, so that the straw is just barely touching the rim, then spin it. Do not allow the forks or swing arm to move. Watch for differences in lateral (side to side) or radial (up and down) runout. Check lateral first by having the straw beside the rim, and radial by having it above or below. Realistically it should be zero, but it can be up to 2mm on some bikes and still be considered acceptable. A cast wheel cannot have the runout changed, you just need to get a new one.

When removing the tire use the curved end of the iron, to reinstall use the straight edge.

Lube (water) makes it a HELL of a lot easier to install or remove a tire.

When beading the tire (adding air) do not exceed 50-60 psi depending on the tire. You can probably do this safely at the gas station, prop it against a wall and stand around the corner though

Ususally you leave the valve OUT when beading a tire, because the air pressure to bead might exceed the air pressure the valve can contain.

Take your time, be careful not to scratch the beading area (don't hammer your irons in there or out).

If you have any more questions feel free to ask, or hit me up on MSN/AIM/ICQ everything is listed below.

A removed bearing is a compromised one, if you applied force to the inner circle to remove it (pulled or punched it out) then you've potentially damaged it, and should not reuse it.

To check for wheel bearing function leave it on the swingarm, or the forks, and holding the frame still try to... well you grab the tire at two spots opposite each other and push one side away and one side towards, then just back and forth. You're checking for lateral movement against the axle. I cannot think of a better way to describe it then that. If you feel any movement at all they need to be replaced. A bearing is engineed to within three ten thousandths of an inch. To fine for you to pick up any movement.

Do this at a couple of spots along the rim (you can rotate it to make it easier) and there should be no play. Spin the rim and listen for catching or rough movement... if you think there's a problem replace them.

Like I said above those are the instructions for doing it, I'll see if I cannot get some pictures of me doing it next time I change one or...

Here is a pic that shows the steps to change a tube-type tire.

You can ignore the part about removing the tube and reinstalling it. you might have trouble breaking the bead with your foot, there are machines that can do it for you. Alternately if you aren't using the same tire ever again just use a table vice to pinch the tire right next to the rim until it pops off teh bead (do not let it hit the rim) and then stomp the rest out.

If you want to check the runout quickly and/or easily, after the tire is off the wheel reinstall the wheel in the swing arm or forks keeping it off the ground. Set up a spray can with a straw on it, so that the straw is just barely touching the rim, then spin it. Do not allow the forks or swing arm to move. Watch for differences in lateral (side to side) or radial (up and down) runout. Check lateral first by having the straw beside the rim, and radial by having it above or below. Realistically it should be zero, but it can be up to 2mm on some bikes and still be considered acceptable. A cast wheel cannot have the runout changed, you just need to get a new one.

When removing the tire use the curved end of the iron, to reinstall use the straight edge.

Lube (water) makes it a HELL of a lot easier to install or remove a tire.

When beading the tire (adding air) do not exceed 50-60 psi depending on the tire. You can probably do this safely at the gas station, prop it against a wall and stand around the corner though

Ususally you leave the valve OUT when beading a tire, because the air pressure to bead might exceed the air pressure the valve can contain.

Take your time, be careful not to scratch the beading area (don't hammer your irons in there or out).

If you have any more questions feel free to ask, or hit me up on MSN/AIM/ICQ everything is listed below.

Of course I'm generalizing from a single example here, but everyone does that. At least I do.

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

- CNF2002

- Site Supporter - Silver

- Posts: 2553

- Joined: Fri Sep 16, 2005 1:56 pm

- Sex: Male

- Location: Texas

This has been great advice.

Someone else suggested also using a big c-clamp to pop the bead.

There is a great video I found on google

http://video.google.com/videoplay?docid ... tire&hl=en

that shows a person changing the tire. Seeing it done really helps get a good feel for what's involved. It really doesn't seem to be as complicated a process as I initially thought.

Someone else suggested also using a big c-clamp to pop the bead.

There is a great video I found on google

http://video.google.com/videoplay?docid ... tire&hl=en

that shows a person changing the tire. Seeing it done really helps get a good feel for what's involved. It really doesn't seem to be as complicated a process as I initially thought.

2002 Buell Blast 500 /¦\

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

[url=http://www.putfile.com][img]http://x10.putfile.com/3/8221543225.gif[/img][/url]

[url=http://www.totalmotorcycle.com/BBS/viewtopic.php?t=11790]Confessions of a Commuter[/url]

- Sev

- Site Supporter - Gold

- Posts: 7352

- Joined: Sun Jun 06, 2004 7:52 pm

- Sex: Male

- Location: Sherwood Park, Alberta

I thought exactly the same thing first time I saw it done, c-clamp, or a table vise, they're the same thing for our purposes. Just don't catch the rim, don't catch the rim, don't catch the rim lol.

Then just lever her off, and lever her back on. Easy as pie.

Any shop should be able to balance it for you.

Then just lever her off, and lever her back on. Easy as pie.

Any shop should be able to balance it for you.

Of course I'm generalizing from a single example here, but everyone does that. At least I do.

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

[url=http://sirac-sev.blogspot.com/][img]http://i12.photobucket.com/albums/a227/Sevulturus/sig.jpg[/img][/url]

-

crazy5dave

- Elite

- Posts: 145

- Joined: Wed Jul 05, 2006 1:57 am

- Sex: Male

- Location: Nagoya, Japan

I am a HD/buell mechanic. i used to work in America now i work in Japan. I have changed several rear tires on Blasts. My guess is, that the reason the dealers dont like them is that the tires are blast only sizes and they dont have any in stock. those tires go on nothing else, they dont go on several models and who owns a blast? sorry they werent big sellers. just a guess.

Forget some of the manual. If you remove a bearing, its trash. Dont worry about that. Having said that. put your fingers in they and rotate. if its smoooth all the way around , no notches, and you have no side play is all good. Checking the radail and lateral run out. When i spin on the balancer, i look, does it move around visiably? no its all good. or just spin it in the alxe on the bike. its a cast wheel if there is run out, it is trash.

You remove the pulley/sporket parts because its impossible to use a tire machine and leave it on. its very close to the edge and it hard to get irons under it and the pulley is large for the wheel and very near the edge of the rim and the brake disc small, so brake disk down, pulley up in the machine.

Heres a secret. you dont need new bolts for the pulley! they say to buy new bolts, because they need loctite. their lawyer wants you to have loctite, so you "must " buy new bolts which are the same with new thread lock on them. why because the laywers say so. CYA! Wire brush off the old loctite and put so new on. done

How many warnings did you see in that manual. Hell farting on the bike "---many cause loss of control leading to death or serious injury". sound familiar.

Breaking the bead by "stomping on it" isnt going to happen. the smaller the wheel and the lower the profile, the harder it is. My old shop had a lower price of $30 to change and balance a tire if it was off the bike. meaning you took the wheel off, went there and gave them the wheel and a new tire, they changed it and balanced it, them you put it back on. have any of those shops around?

Forget some of the manual. If you remove a bearing, its trash. Dont worry about that. Having said that. put your fingers in they and rotate. if its smoooth all the way around , no notches, and you have no side play is all good. Checking the radail and lateral run out. When i spin on the balancer, i look, does it move around visiably? no its all good. or just spin it in the alxe on the bike. its a cast wheel if there is run out, it is trash.

You remove the pulley/sporket parts because its impossible to use a tire machine and leave it on. its very close to the edge and it hard to get irons under it and the pulley is large for the wheel and very near the edge of the rim and the brake disc small, so brake disk down, pulley up in the machine.

Heres a secret. you dont need new bolts for the pulley! they say to buy new bolts, because they need loctite. their lawyer wants you to have loctite, so you "must " buy new bolts which are the same with new thread lock on them. why because the laywers say so. CYA! Wire brush off the old loctite and put so new on. done

How many warnings did you see in that manual. Hell farting on the bike "---many cause loss of control leading to death or serious injury". sound familiar.

Breaking the bead by "stomping on it" isnt going to happen. the smaller the wheel and the lower the profile, the harder it is. My old shop had a lower price of $30 to change and balance a tire if it was off the bike. meaning you took the wheel off, went there and gave them the wheel and a new tire, they changed it and balanced it, them you put it back on. have any of those shops around?

- Skier

- Site Supporter - Platinum

- Posts: 2242

- Joined: Sat Aug 07, 2004 10:44 am

- Sex: Male

- Location: Pullman, WA, USA

Tire changing really isn't too tough, and pays for itself real quick if you ride a lot. You can get some Harbor Freight cheap tools, some free guides and a bit of sweat, and you've saved anywhere between $30 and $60 a tire.

If you shop around, you can also find a dial indicator with magnetic base for $50 or so. As an additional bonus, you're no longer at the mercy of the shops around you. No schedule juggling for you!

If you shop around, you can also find a dial indicator with magnetic base for $50 or so. As an additional bonus, you're no longer at the mercy of the shops around you. No schedule juggling for you!

[url=http://www.motoblag.com/blag/]Practicing the dark and forgotten art of using turn signals since '98.[/url]