Wait wait wait, you need to replace your wheel bearings etc etc etc? Or just replace the tire?

You don't need a stand to do the tire replacement, I've been using a piece of cardboard on the floor to prevent scratches. Rim protectors are just pieces of plastic that fit over the rim so you don't scratch it. Wrap your tire irons in duct tape.

Checking rim runout can be done with the axle and a spray can... but I thought Buell's have cast wheels (no spokes) so you don't need to check them for runout. They are either true or they are "messed" and need to be replaced. If a cast wheel isn't correct, there's no way to fix it.

So you need:

2 tire irons

water (or some tire approved lube but we use water).

You'll be paying for the new bolts and washers regardless.

If you get it mounted, I'll bet you money nearly any shop will balance it for you.

If you remove the bearings they should be junked regardless, because you're going to be brinelling them with the force that you're putting on them, so a pick and a hammer is good enough, just make sure you don't pound them back in. But you only need to replace bearings if yours are shot.

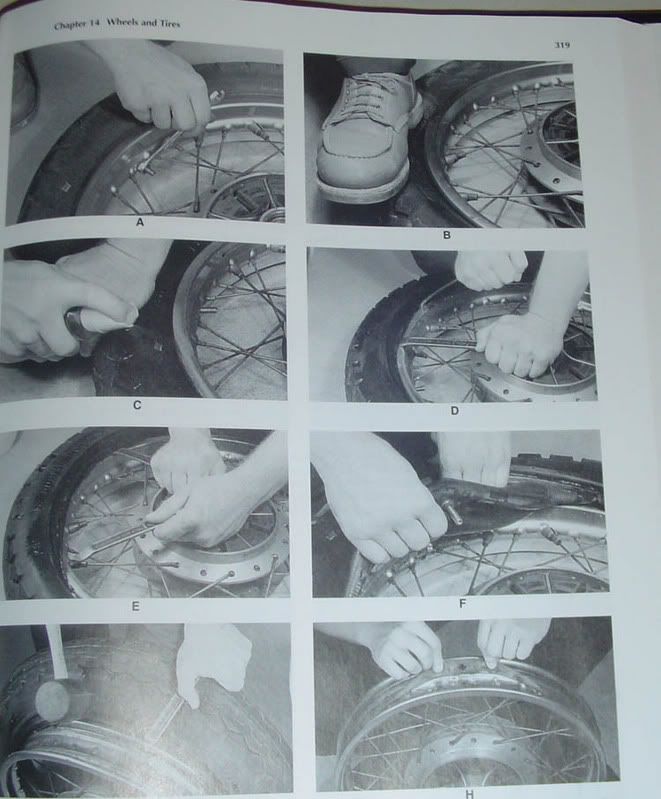

The short version of what to do is:

1) let the air out

2) remove the valve in the valve stem

3) lay the tire on its side on a piece of cardboard and step on the rubber to break the bead off the rim

4) flip over and repeat

4) a) lube the bead (lip) with water

5) fit the curved end of one of your tire irons under the bead (lip) of the tire and lever it up over the rim, place the other 5 inches away and do the same

6) work your way around until you've got 1 whole side off

7) do the same thing for the other side of the tire, making sure you pull it off to the same side

throw away old tire

9) lube the new tire with water

10) line the light spot (part with a dot) of the tire up with the valve stem

11) starting at the valve stem shove the tire onto the rim making sure to push evenly

12) use the flat side of the tire iron to push the first bead over the rim taking small 4-5 inch sections at a time

13) use the flat side of the tire iron to push the other side of the tire on the wheel in small sections, take your time standing on the part you started will help to keep it in place

14) lube the beads again with water and put air into it you will hear 2 pops (maybe BANGS) as the tire fits into the beads

take it to a shop to be balanced OR

15) balance it by putting it through the axle and resting the axle on a level surface (it MUST be level)

16) spin the tire a couple of times, marking the lowest spot each time

17) add weight opposite that spot (highest)

18) only add weight to one place otherwise you can negate weights that you've already added, but continue to add weights until the tire does not stop in the same spot twice

replace the cheap taped on weights with real weights and you're good to go

it is not necessary to spin the wheel really hard when you are balancing

It's not easy the first couple of times, but once you get used to it, you can do it in 10 minutes. 2 weeks ago I wouldn't know which side of a tire iron to hold.