Back to the Model History Timeline Review Page

2002 to 2003 – Redefined – Third generation R1/YZF-R1

Page 4 of 7

<< Page Back – Page Forward >>

“The ultimate cornering Master (Yamaha R1/YZF-R1)” – Yamaha

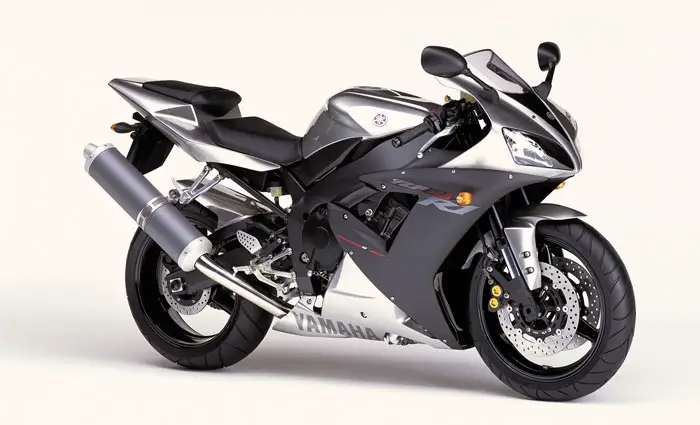

2002 Yamaha R1/YZF-R1

A new generation of R1 was developed for (even) better cornering performance and more control for the rider.

A completely new frame (with detachable sub-frame) was developed and optimized to work with the new front forks and new rear suspension. The front end geometry was fine-tuned and the fork inner tubes were increased in diameter from 41 to 43 mm. The front fork stroke was reduced from 135 to 120 mm providing better control and feeling when braking and cornering.

The new engine was mounted higher in the frame which is much closer to the rolling axis of the bike. A fuel injection system was added and met the tougher EU2 emission standards with ease.

The fundamental dimensions and architecture of the engine was inherited from the original R1 but the vast majority of the components were new. The air intake was controlled by a ‘suction piston’ type of valve to ensure a smooth and direct throttle response. Bore x stroke was now 74 x 58 mm and the airbox intake was altered to face forward accessing cooler air. As a result of these changes the HP was increased to 152 and dry weight was reduced to 174 kg.

The bodywork was again completely new. The exhaust system was changed to a 4 into 2 into 1 layout and now completely made of titanium, including the header pipes.

The new, asymmetrical swingarm allowed an unobstructed route for this exhaust system. The wheels were lighter and the new brake system was easily recognizable by the orange callipers that replaced the blue ones on previous models.

One additional detail improvement was made with the addition of a shift indicator lamp.

2003 Yamaha R1/YZF-R1

2003 saw another colouring and graphic change to keep the YZF-R1 popular with the most up-to-date riders.

2002 – 2003 Yamaha YZF-R1 : A closer look at engineering details

The development priorities of the new R1 are handling and controllability. What are the engineering ingredients that make the bike faster in corners and at the same time even easier to handle?

“It is very reassuring to see the result of the web questionnaire”, Yoshikazu Koike looks with a smile to the facts and figures on paper “almost 75% of the many thousands of respondents mentioned, that cornering performance is more important to them than just simple horsepower or top speed”.

This confirms the desire of most supersport riders to enjoy sport bikes in an environment they are made for: winding roads and tracks.

Lets have a closer look at the solutions behind the R1, to achieve the targets that have been laid down in the concept catalogue.

The following is a summary of the most important features of 2002 model R1 (of course there are lots of other changes too…).

The main areas:

Chassis

– Mass concentration around the rolling axis

– High chassis rigidity

– Refined steering assembly and front suspension setting

Engine

– Sensual Throttle Response

– Enhanced over-rev characteristics

– Other detail solutions

Chassis – Part 1

Target of development – Mass concentration around the rolling axis.

R1 components placed as near as possible around the rolling axis to improve

– Linear banking character

– Quick handling

This is achieved by:

1. Engine position 20 mm higher and therefore near to the rolling axis

2. Asymmetrical swingarm to allow the muffler to be placed with a narrower routing close to the body

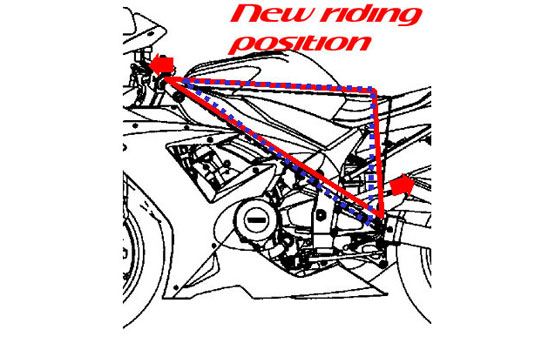

3. Revised Riding Position

The 20 mm higher engine position brings the main masses nearer to the rolling axis. The rolling axis of the bike is a hypothetical line, which changes position during riding, depending on the forces applied to the machine. This axis is the key for the handling character of a motorcycle. The less mass one has to move at a distance around this axis, the easier the bike feels when going into and out of corners.

The muffler needs to be placed as close as possible to the bikes body. This allows sufficient ground clearance during cornering and also concentrates the mass of the whole exhaust system near to the rolling axis. To achieve this the swingarm of R1 is asymmetrical, in order to allow the muffler to be placed “inside”.

The rider’s weight has a great influence on handling character. Just like the other components of a bike, ideally the rider should be placed as near as possible to the rolling axis. However comfort and ergonomics of man needs to be considered too and is usually contradictory to pure engineering requirements. The Riding position of R1 has been changed considering both factors. As you can see in the illustration (red line is new R1, blue line is 2001 model), footrest position is moved backwards and handlebar position is further forward. To balance the riders weight distribution in a better way.

Chassis – Part 2

Target of development – High chassis rigidity

R1 rigid chassis will result in

– Sharp response to riders input (steering braking etc.)

– Precise feedback from riders action and road surface and condition

This is achieved by:

1. Deltabox III chassis with 30% increased rigidity

2. Rigid new swingarm

3. 43 mm front fork (2 mm size up at same weight)

4. One piece forged handlebars (to transmit the precise feedback to the rider)

The Deltabox III represents the 3rd generation. This chassis is lighter and has a 30% increased rigidity and new geometry. Also the rear sub-frame is detachable.

The swingarm has a new asymmetrical layout. To avoid interference with exhaust pipes, the right-hand side is curved. Also the rigidity of the unit itself is in line with the new Deltabox III chassis.

The front fork diameter increased from 41mm to 43 mm. The increased rigidity of the fork was a necessary result of the new chassis layout and contributes to direct feel for the road and general stability.

It seems a small thing at first, but the new forged handlebars contribute to the direct feedback between rider and road. The enhanced rigidity of these aluminum bars allow very little flex during operation and improve the feeling for what is happening through the front steering assembly

Chassis – Part 3

Target of development- Refined steering assembly and front suspension setting

A new front fork and suspension setting results in

– Active banking character into corners

– Possibility to accelerate earlier and with better grip out of corners

This is achieved by:

1. New steering assembly settings

a. Reduced Fork Offset 25mm (-10mm)

b. Increased trail 103mm (+11mm)

2. Reduced Front Fork Stroke of 120mm (-15mm) for reduced pitching

3. New Swing-arm pivot axis position:

a. Raised by 17.5 mm

b. Increased angle (11.8°)

4. Higher spring rates, increased damping setting range and adjustment possibilities.

The offset reduction by 10 mm had a positive effect on handling, and the increased trail of 11 mm (now 103 mm total) increased feedback and cornering stability at the same time.

The stroke was reduced from 135 mm to 120 mm. This reduces pitch and movement of the machine during acceleration and braking and contributes significantly to stability in cornering and at the same time increases feedback from road surface.

The swingarm pivot position has been raised by 17,5 mm. As a result the swingarm angle was increased. This contributes to better traction during acceleration, in particular out of corners, due to a better absorption of the chain forces influencing the rear wheel.

The spring rates of front and rear suspension were increased, to adapt to the higher rigidity of the chassis. Also the adjustment range has been increased and the rider can select between 20 steps of adjustment both on front and rear suspension.

Engine – Part 1

Target of development- Sensual Throttle Response

In order to enable the rider to perform

– Early throttle opening out of corners

– Precise performance control

This is achieved by:

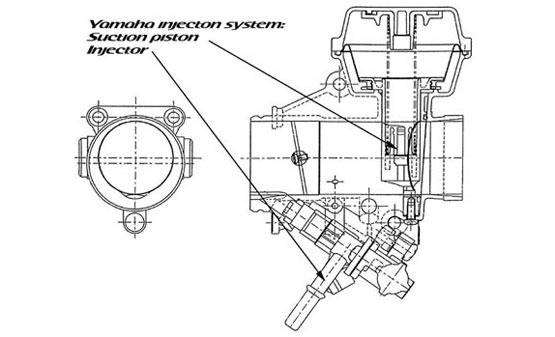

1. Fuel Injection with Suction Piston Intake System (Yamaha patented system)

2. Dual EXUP system with compact layout and 2-shaft design (-500 g)

Fuel injection guarantees a precise “digital” mixture of fuel and air and is a good feature to ensure low emissions and best mixture setting throughout the whole rpm range. Carburetors on the other hand have a better “analogue” response feeling and a smoother throttle pick up. The R1 new FI- system combines both system advantages. A suction valve acts like a carburetor and regulates the throttle pick up and a direct injection contributes with the correct mixture, microchip controlled and feed with information from several sensors. The result is a better throttle control which enables the rider to activate the right amount of power at any engine revolution almost linear to throttle grip operation.

The EXUP system is a valve to consol the gas flow in the exhaust system, to strengthen the engine character (in particular in midrange). The new system has 2 valves instead of one and is smaller and lighter. It operates electronically controlled, taking gear position and engine revolution into consideration. A new high torque electric motor improves responsiveness and drivability.

Engine – Part 2

Target of Development- Enhanced over-rev characteristics

To make efficient use of wider power band

This is achieved by:

1. Electronic fuel injection management

2. New air-cleaner box with forward facing air intake

3. New exhaust layout 4in2in1 system

Yamaha new fuel injection system, enables the rider to “over-rev” the engine , while still keeping a proper fuel & air mixture. There is no engine “cough” on high revolutions, when the rider decides for no shift up between corners.

To supply cooler air to air-box, the air intake has been moved forward. Fresh air enters the air-box from the front of the motorcycle directly. Cooler air has a higher density and this is beneficial to performance output.

The new exhaust layout routes the 4 pipes into a 2 pipe chamber and then into the single pipe connecting the muffler. This construction increases engine character and boosts performance in midrange.

Engine – Part 3

Other detail solutions to support development targets:

1. New brake system to increase performance and controllability

2. High silicon-content alloy cylinder sleeve and new design piston rings

3. Uprated carburised connecting rods

4. Lighter exhaust valves

5. Iridium spark plugs

6. Better cooling: New radiator and oil cooler

The brake system features new calipers to increase brake performance and controllability. The pistons of the front calipers are changed to alloy and new sintered pads are used. Also the hand-lever ratio has been changed. To balance the brake forces between front and rear, the rear brake caliper has been changed to a 2piston type and the disc diameter could be reduced by 25 mm to now 220 mm (for light weight).

The new aluminum sleeves have a higher silicon content, in order to decrease oil consumption and at the same time to ensure lowest friction between piston and sleeve. The new piston rings have different material in order to fit to the new sleeves.

The new up rated carburised connecting rods have highest rigidity at a low weight.

Lighter exhaust valves ensure a higher engine revolution combined with high reliability.

The new Iridium spark plugs ensure a more stable combustion. Iridium melting point is very high (2150 degree centigrade) , and therefore has a higher heat resistance than normal spark plug. The durability is 1.5 times longer than a normal spark plug at the same condition.

Keeping the engine cool results in better performance even in “hot” conditions. The new radiator in combination with a higher performance fan has increased cooling capacity by a 20 % better airflow, comparing to previous model. Also 20% increase in cooling capacity was achieved by a new oilcooler layout.

YZF-R1 Third vs Fourth generation: The real stuff

There has never been a bike running off Yamaha’s production line, that had more influence from GP and World Superbike than the third generation R1.

An extreme machine like the R1 usually provokes the same doubtful question: Lighter, faster, more radical- when does this development come to an end? The answer is as simple as it is obvious: there will never be an end to technical development. Approaching the question from a philosophical point of view, we need to ask the question: why should there be an end to these developments? The new R1 is simply better than ever before. And better does not mean only more powerful and faster. There is a more sophisticated, holistic development philosophy behind the R-series.

Leading motorcycle development

Let’s have a brief look back in history: Development in the seventies and early eighties focused a lot on increase of horsepower. When the first 100 HP machines appeared, the same doubtful question was raised. But brakes and chassis technology improved a lot in the following years and a 100 HP machine was easier to handle than a 50 HP machine a couple of years earlier. Supersport machines like the FZR 1000 in 1988 and ultimately the first R1 in 1998 became more powerful, but at the same time they became more controllable and lighter due to use of aluminium chassis components, better brakes, better suspension and new design and layout. No doubt, supersport is leading motorcycle developments and there is a lot of spin off to other bike categories, which benefit from supersport technology.

However the goalposts have changed in the recent years. The first R1 focused on lightweight, the second generation in 2002 focused on controllability and handling. The third generation R1 has a more holistic development philosophy, the focus is on the rider’s viewpoint of what the most ideal supersport machine should be: most powerful, excellent handling and still controllable.

Humachine Technology

The R1 development team consists of a bunch of enthusiasts themselves, who acquired unique skills in the various areas of motorcycle design: from engine, chassis and suspension, to ergonomics, aerodynamics and material science. The result of their work is an entirely new bike with not only unmatched specification, but also it is the pinnacle of what Yamaha calls “Humachine Technology”. The phrase is an abbreviation of human & machine and stands for a holistic approach which will make the rider feel excited and, at the same time, confident on such a high performance machine regardless of his skill and speed.

Yamaha’s test riders have a deep knowledge base of how a bike should handle. One of them is an ex-professional racer: “It was hard work to get every single component of the bike to work as we wanted it. But the new R1 is now just breathtaking. With 170 to 180 HP (depending on ram air pressure) at my fingertips, I could never feel the bike would be out of control. It just handles in a way we could not imagine a few years ago.”

This is not only the low weight with a power to weight ratio of 1:1, but it is the integration of parts into each other. For example the engine construction was significantly influenced by chassis & handling requirements. That’s the reason why the new power-plant has a 40° cylinder angle to give the frame more room for a straight line from headstock to pivot point at the rear swing arm axle, resulting in a 200 % stiffer frame!

The base layout of the engine is based on the GP1 racer, and the bore was increased by 3 mm with a shorter stroke to enable higher rpm. Usually this would result in a 12 mm increase in width of the engine but the engine block is only 2,8 mm wider. To achieve this the cylinder pitch was reduced to levels never reached before. However, by moving the generator behind the cylinder block the total engine size could be even further reduced, so that the engine as a package is smaller than ever before!

Communication between man and machine

The test rider is convinced: “For me the key word for R1 is high control feeling. Front end feel is the key to fast corner entry, for rapid corner exit you need stability and good traction. The problem we were confronted with this high performance engine was to find a good suspension balance during hard acceleration because this powerful engine upsets the rear suspension especially in the lower gears. We solved it and I think the new R1 is as close to a race bike as you can get while still having a fantastic road bike at the same time.”

Because of this high control feel the rider is confident and he will enjoy the R1’s incredibly quick turn-in characteristics and rapid corner exits.

He explains further: “The gearbox also plays an important role in the R1 cornering ability. It is a real race close ratio gearbox, where you always find a best gear for a certain corner and you will always be in the right rpm range. A four stroke engine has to run in the right rpm range during cornering because of its rotating mass. If the engine is revving too low during cornering the bike will under steer. That is why the gearbox is so important for this bike.”

A lot of this knowledge materialised in the new R1 came from Yamaha MotoGP machines. This bike does exactly what the rider wants. Both experts and average riders can experience this behaviour and thrill. And that is what makes the new R1 so exciting!

Not a replica, but the real stuff

Unlike racer replicas which copy the outside of racer machines, the new R1 is based on the inner virtues of a racing machine. There is no artificial styling or gimmick, every part has a function and contributes to the bikes total performance.

The R1 is a perfect example of a mechanical beauty that results when form truly expresses its function. That is the true aesthetic attraction of the new R1. In simple terms: “What you see is what you get.”

YZF R1: ALL-NEW ENGINE

A whole new world of performance

The engineers have developed an all-new in-line four cylinder powerplant whose genetic make up is heavily influenced by the very latest MotoGP-developed technology.

The new engine on the third generation R1 is the most advanced design ever used on a production Yamaha, and by using the very latest race-bred systems and designs, maximum power output is boosted by over 13 per cent to 172 HP at 12,500 rpm, a figure which rises to 180 HP with the forced air intake operational!

Optimized 40 degree cylinder angle

Yamaha’s R-series models have always been developed using a holistic approach in which every single component is developed not only to perform its own specific role efficiently, but also to complement the performance of all other components wherever possible.

An excellent example of this totally integrated design philosophy can be seen in the adoption of the new cylinder layout, which is angled forwards at 40 degrees.

This configuration is similar to the layout used on Yamaha’s MotoGP racing machinery, and it allows greater freedom in the development of a much stiffer chassis. By sloping the engine forwards at 40 degrees, the new generation R1 frame has a virtually straight, unimpeded run from the headstock through to the swingarm pivot point, which, in chassis terms, is an idealised layout.

There are two major benefits from using this 40 degree engine position. Firstly, because the main spars are now able to take the most direct path to the swingarm pivot, the new R1’s frame rigidity is increased significantly. Secondly, because the cylinder head now sits below the route of the twin spars, the overall width between the spars is greatly reduced.

This in turn allows the fitment of a slimmer fuel tank, which makes for a more comfortable and aerodynamic riding position.

Bigger bore closed-deck cylinder

In the quest for greater power Yamaha’s engineers have increased bore size to 77 mm, while stroke is reduced to 53.6 mm, and this free-revving shorter stroke engine now delivers peak power at 12,500 rpm, some 2,000 rpm higher than previously.

The new closed-deck cylinder design offers high levels of rigidity, and this has made it possible to reduce the thickness of alloy between each individual cylinder bore to only 5mm.

Because the new frame is much stronger, the new 40° slant block motor is no longer employed as a fully-stressed member, and the new cylinder is now separate from the upper crankcase, and not a unified design as seen on the ’03 model.

Compact high-compression cylinder head

One of the significant performance enhancing components on the new R1 is its newly designed cylinder head. The DOHC 5-valve layout now features narrower valve angles, with the centre intake valve set at 8.75 degrees, while the outer intake valves are angled at 15.75 degrees, and the two exhaust valves positioned at 11 degrees.

The shape of the ports and combustion chamber design has also been modified, and the squish area has been changed to give a higher compression ratio of 12.4:1

Lightweight low-inertia internals

New 77mm diameter short-skirt forged pistons and new carburised connecting rods drive a lightweight crankshaft assembly, and although this new set-up is designed to handle higher engine speeds and increased levels of power, it is actually lighter than the 2003 machine’s design. The reduced inertia of the ’04 engine internals complements the free-revving character of the new shorter stroke engine, to give the new R1 excellent throttle response over a very wide range of engine speeds.

Compact fuel injection system with motor-driven secondary throttle valves

The third generation R1 uses a new fuel injection system featuring twin valve throttle bodies, and this highly advanced new fuel supply system features digitally-controlled motor-driven secondary butterfly valves that actively control the air flow. The result is class-leading driveability and linearity together with precision throttle response that makes for previously unattainable levels of controllability.

Yet, at the same time as being a high-tech digitally-controlled design, the quality and characteristics of this new fuel injection system have ultimately been set by the test riders that spent many hours fine tuning the mapping.

As well as being one of the most advanced fuel supply systems in the supersport class, this is also one of the most compact, as it has to fit in between the spars on the new slimline frame. By reducing the pitch between the throttle bodies the overall dimensions have been minimised, and this sophisticated new digitally-controlled system is as compact as that fitted to a 600.

Forced air intake

As well as increasing performance at higher speeds, this new forced air intake system offers a number of other important advantages. The much smaller airbox required by this forced air system takes up less space above the engine, and this allows the fitment of a slimmer fuel tank.

Once again, this demonstrates how Yamaha’s holistic approach to supersport machine design offers a wide range of advantages to the third generation R1 rider.

Lightweight close-ratio tri-axis transmission and compact clutch

Like its predecessor, the third generation R1 features Yamaha’s innovative space-saving tri-axis ‘stacked’ transmission whose staggered shaft configuration makes for extremely compact front-to-rear engine dimensions.

To optimise the performance from the more powerful and higher revving engine which now pushes out 172 HP at 12,500rpm, a new close ratio 6-speed transmission has been developed.

Lightweight titanium underseat exhaust system

One of the most significant stylistic changes seen on the new R1 is the compact new 4-into-1-into-2 underseat exhaust system. This beautifully designed system is manufactured from titanium, and as well as being lighter than the conventional layout, it also offers greater aerodynamic efficiency.

Tucked beneath the seat, the dual titanium mufflers give the R1 a slim and aggressive looking rear end, and the system has been tuned to emit a deep, strong growl that gives more than a hint that this is the most powerful Yamaha supersport ever.

The torque-boosting EXUP (Exhaust Ultimate Powervalve) system is situated where the four header pipes flow into one, and features a titanium butterfly valve for the first time.

New curved radiator design

For high levels of cooling efficiency, and also to accommodate the new 40 degree slant of the new engine, a new curved radiator is fitted. This lightweight design is wider and not as tall as the existing system, and features dual ring fans for efficient operation in all conditions.

Water-cooled oil cooler

Yet another example of Yamaha’s attention to detail and desire to minimise weight is the use of a water-cooled oil cooler which is situated at the front of the lower crankcase.

Lightweight AC Magneto

A compact new gear-driven AC magneto which is situated behind the cylinder is as well helping reduce engine width which to allow for greater lean angles and to decentralise mass.

Engine Technical Highlights

– Totally redesigned in-line four cylinder DOHC 5-valve engine

– Maximum power 172 HP @ 12,500 rpm

– 180 HP @ 12,500 rpm with forced air intake

– 40 degree cylinder angle

– Redesigned cylinder head with narrow valve angle

– Increased compression ratio

– Redesigned combustion chamber

– High-lift camshafts

– Electronic fuel injection with motor-driven secondary throttle valves

– Forged pistons, carbonised conrods and lightweight crankshaft

– Reduced internal inertia

– Direct ignition

– Lightweight close-ratio 6-speed transmission

– Compact clutch

– Forced air intake system

– Separate closed deck cylinder

– Reduced pitch between cylinder bores

– Wider curved radiator with dual ring fans

– Titanium 4-into1-into-2 exhaust system with twin up-mufflers

– Lightweight EXUP system with titanium butterfly valves

– Water-cooled oil cooler

– Compact gear-driven ACM located behind cylinders

2002 Yamaha R1/YZF-R1 Specifications

Engine

Engine type Liquid cooled, 4-stroke, forward inclined parallel 4 cylinder, DOHC 20 valves

Displacement 998 cc

Bore x stroke 74.0 x 58.0 mm

Compression ratio 11.8 : 1

Maximum power 111.8 kW (152 HP) @ 10,500 rpm

Maximum torque 104.9 Nm (10.7 kg-m) @ 8,500 rpm

Lubrication system Wet sump

Fuel System Mikuni FI

Clutch type Wet, multiple disc

Ignition system TCI (digital)

Starter system Electric

Transmission system Constant mesh, 6 speed

Primary reduction ratio 1.581

Secundary reduction ratio 2.688

Final transmission Chain

Ratios gearbox 1st 2.5

Ratios gearbox 2nd 1.842

Ratios gearbox 3rd 1.5

Ratios gearbox 4th 1.333

Ratios gearbox 5th 1.2

Ratios gearbox 6th 1.115

Chassis

Front suspension system Telescopic fork

Front suspension adjustability Swingarm (Link suspension)

Front wheel travel 120 mm

Rear wheel travel 130 mm

Caster angle 24°

Trail 103 mm

Front brake Dual discs, Ø 298 mm

Rear brake Single disc, Ø 220 mm

Front tyre 120/70 ZR17M/C (58W)

Rear tyre 190/50 ZR17M/C (73W)

Dimensions

Overall length 2,035 mm

Overall width 705 mm

Overall height 1,105 mm

Seat height 820 mm

Wheelbase 1,395 mm

Minimum ground clearance 140 mm

Dry weight 174 kg

Fuel tank capacity (reserve) 17 L

Engine oil tank capacity 3.8 L

Specifications and appearance of Yamaha products shown here are subject to change without notice and may vary according to requirements and conditions. For further details please consult your Yamaha dealer.